PRODUCTS

Choosing the Right Hydraulic Cylinder Material for Durability and Efficiency

2025-07-16

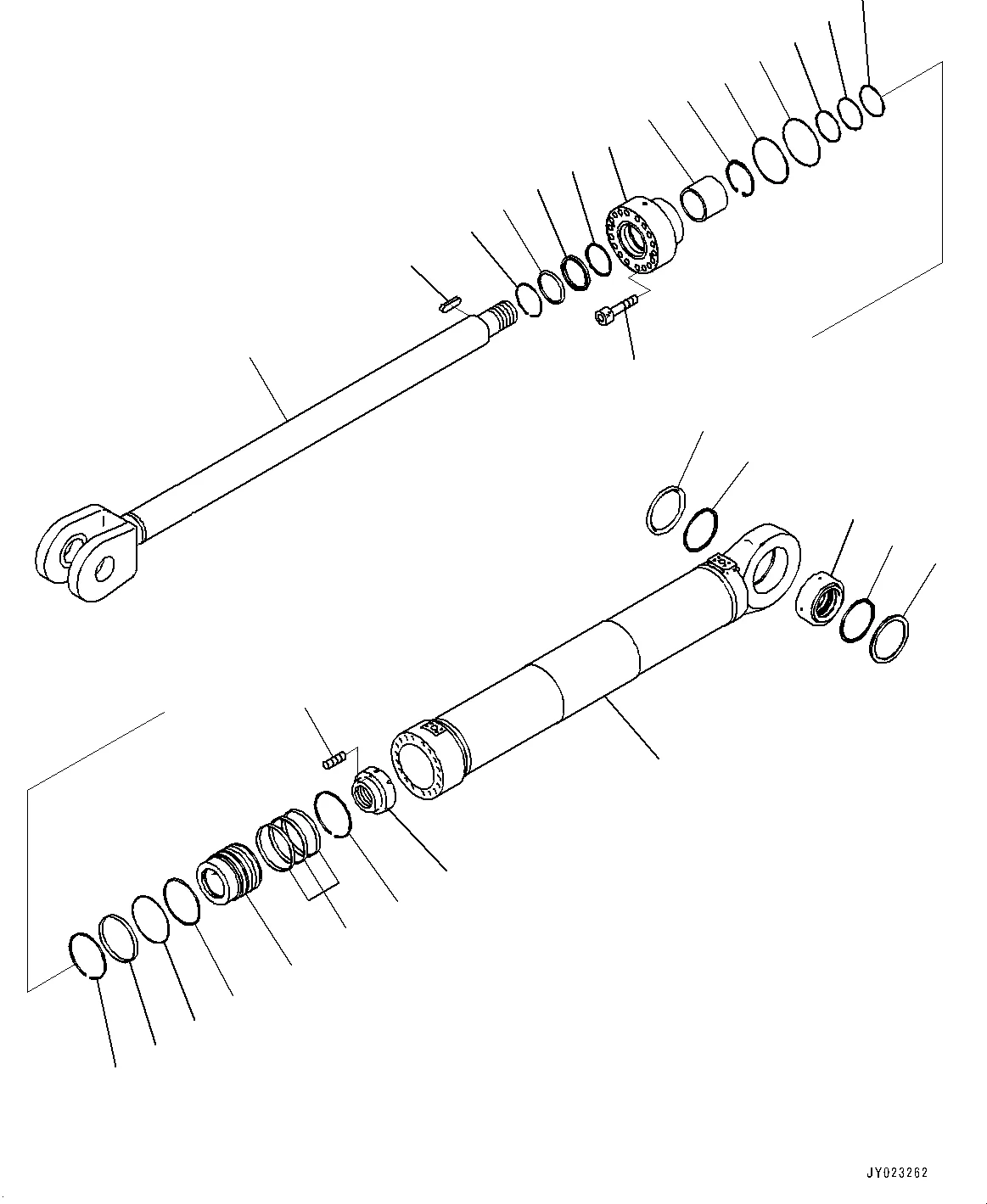

Selecting proper hydraulic cylinder materials is essential for their long-lasting and effective performance. Material Selection focuses on a number of considerations that affect the choice, durability, performance, and cost of the part. Choosing the wrong material can result in failure of the material, expensive repair costs, and costly downtime of the system. Let\'s explore some key aspects. Material Strength and Hardness

The cylinder needs to be able to handle the internal high pressure and external forces. Alloy steels are very easy to build for high-strength and hard-use applications, making steel a common metal for applications that involve high amounts of torque. Now different grades of steel have different properties; some are more resistant to corrosion and some have a better tensile strength. The right steel grade depends on particular pressure and load requirements of the application.

Cast iron is more cost effective and provides relatively good compressive strength, but cannot match the tensile strength of steel. In niche cases where wear or corrosion resistance must be extreme, then stainless steel or specialized hard-chromed surfaces are required.

Corrosion Resistance

A lot can affect the life of a cylinder, from fluids to environmental conditions. Corrosion resistance is important in certain places that use harsh chemicals or high humidity. Stainless steel has better corrosion resistance than regular carbon steel and the higher upfront cost is often offset by lower maintenance costs. Less costly materials may feature additional corrosion protection such as zinc plating or powder coating.

Cost Considerations

Material properties are important but cost is very important. For a number of applications, steel continues to be an economical choice and a good compromise between price and performance. Other materials, like exotic alloys or composites, are more expensive and only worth it when their improved properties are necessary for the application.

In the end, the right material is a compromise between the required performance properties, the corresponding conditions under which it will operate, and the available budget. Analysis allows for best cylinder performance and a longer life cycle.

The cylinder needs to be able to handle the internal high pressure and external forces. Alloy steels are very easy to build for high-strength and hard-use applications, making steel a common metal for applications that involve high amounts of torque. Now different grades of steel have different properties; some are more resistant to corrosion and some have a better tensile strength. The right steel grade depends on particular pressure and load requirements of the application.

Cast iron is more cost effective and provides relatively good compressive strength, but cannot match the tensile strength of steel. In niche cases where wear or corrosion resistance must be extreme, then stainless steel or specialized hard-chromed surfaces are required.

Corrosion Resistance

A lot can affect the life of a cylinder, from fluids to environmental conditions. Corrosion resistance is important in certain places that use harsh chemicals or high humidity. Stainless steel has better corrosion resistance than regular carbon steel and the higher upfront cost is often offset by lower maintenance costs. Less costly materials may feature additional corrosion protection such as zinc plating or powder coating.

Cost Considerations

Material properties are important but cost is very important. For a number of applications, steel continues to be an economical choice and a good compromise between price and performance. Other materials, like exotic alloys or composites, are more expensive and only worth it when their improved properties are necessary for the application.

In the end, the right material is a compromise between the required performance properties, the corresponding conditions under which it will operate, and the available budget. Analysis allows for best cylinder performance and a longer life cycle.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)