PRODUCTS

Exploring Material Options for Hydraulic Cylinders Enhanced Performance and Cost

2025-07-14

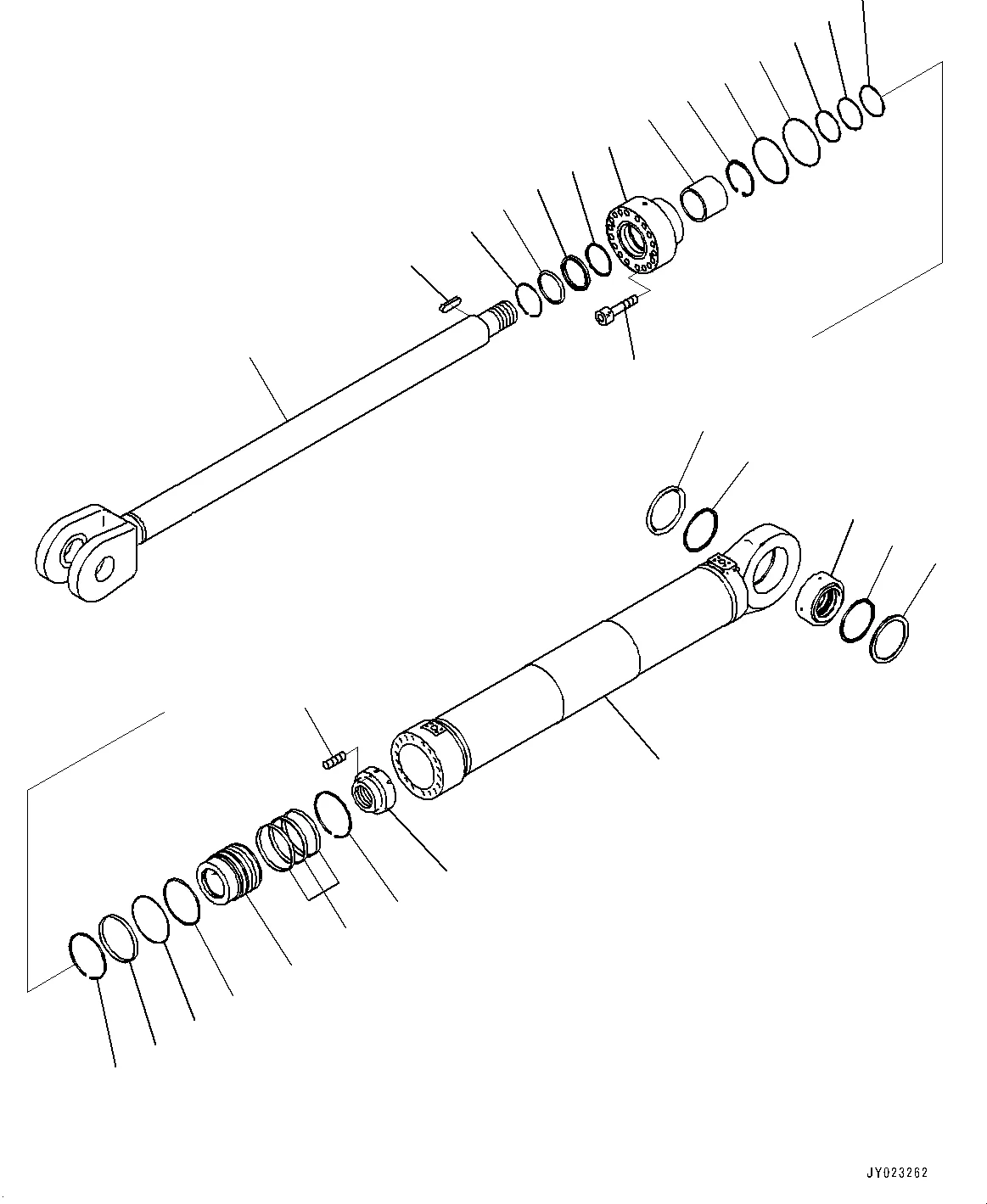

Finding the best hydraulic cylinder material is one of the utmost importance when it comes to making the most of the hydraulic function while keeping the costs in check. Hydraulic systems are found everywhere from heavy machinery to manufacturing to a multitude of industrial applications, requiring components to withstand extreme pressures and operating conditions. Material selection affects the durability, service life, and efficiency of the cylinder; it can have a significant impact on the total cost of ownership. Strength and Durability

In the past, high strength steels like alloy steels and quenched and tempered steels were purportedly preferred due to their resistance to high pressures and cyclical loading. These materials provide great tensile strength, yield strength preventing the cylinders from failure even if they are used in extensive operations.

But it is now undergoing a greater research use for advanced materials such as composite materials. This can be valuable in making the cylinders lighter weight, which should ultimately reduce energy input and make it more efficient. However, more study needs to be done on the longevity and fatigue resistance of these types of devices.

Corrosion Resistance

Corrosion is another important Consideration for hydraulic cylinder repair especially for hydraulic cylinders that are designed to work outdoors. Stainless steels can resist corrosion better than carbon steels, which can help extend the life of the cylinder and lower maintenance costs.

Applications in metal plating, especially chrome plating and specific polymer coatings also provide corrosion and wear protection. The coating is a combination due to the various operating environment and require the desired protection.

Cost Considerations

The material cost is one of the major categories while estimating the cost of the hydraulic cylinder. High-strength alloys and stainless steels deliver even better performance but tend to cost more than standard carbon steels.

The cylinder must balance the material cost, performance requirements, and its lifetime. Because material choices should never be based solely on capital costs, lifecycle cost can help to consider maintenance, labor, and replacement costs to find the most economical solution.

In the past, high strength steels like alloy steels and quenched and tempered steels were purportedly preferred due to their resistance to high pressures and cyclical loading. These materials provide great tensile strength, yield strength preventing the cylinders from failure even if they are used in extensive operations.

But it is now undergoing a greater research use for advanced materials such as composite materials. This can be valuable in making the cylinders lighter weight, which should ultimately reduce energy input and make it more efficient. However, more study needs to be done on the longevity and fatigue resistance of these types of devices.

Corrosion Resistance

Corrosion is another important Consideration for hydraulic cylinder repair especially for hydraulic cylinders that are designed to work outdoors. Stainless steels can resist corrosion better than carbon steels, which can help extend the life of the cylinder and lower maintenance costs.

Applications in metal plating, especially chrome plating and specific polymer coatings also provide corrosion and wear protection. The coating is a combination due to the various operating environment and require the desired protection.

Cost Considerations

The material cost is one of the major categories while estimating the cost of the hydraulic cylinder. High-strength alloys and stainless steels deliver even better performance but tend to cost more than standard carbon steels.

The cylinder must balance the material cost, performance requirements, and its lifetime. Because material choices should never be based solely on capital costs, lifecycle cost can help to consider maintenance, labor, and replacement costs to find the most economical solution.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)