PRODUCTS

Exploring the Diverse World of Hydraulic Pump Types and Their Applications

2025-08-02

The world of hydraulics is a large ecosystem connected by hydraulic pumps, the oft-underrated powerhouse of hydraulics. From construction equipment to aerospace engineering, each hydraulic system has many types and specific applications that need to be comprehended by any professional in the industry. In this exploration into hydraulic pumps, we dig into the unique features that lend them appropriately to certain applications. Gear Pumps

Pump Types Gear Pumps: One of the simplest types of pumps, gear pumps use meshing gears to draw fluid into the pump and push it back out under pressure. They are well-built, inexpensive, and flow at a relatively unchanging rate. On the other hand, they become less efficient in high-pressure conditions and can wear out over time.

Gear pumps are mainly used in low pressure, high volume applications like industrial machinery, lubrication systems, and low pressure hydraulic systems.

Piston Pumps

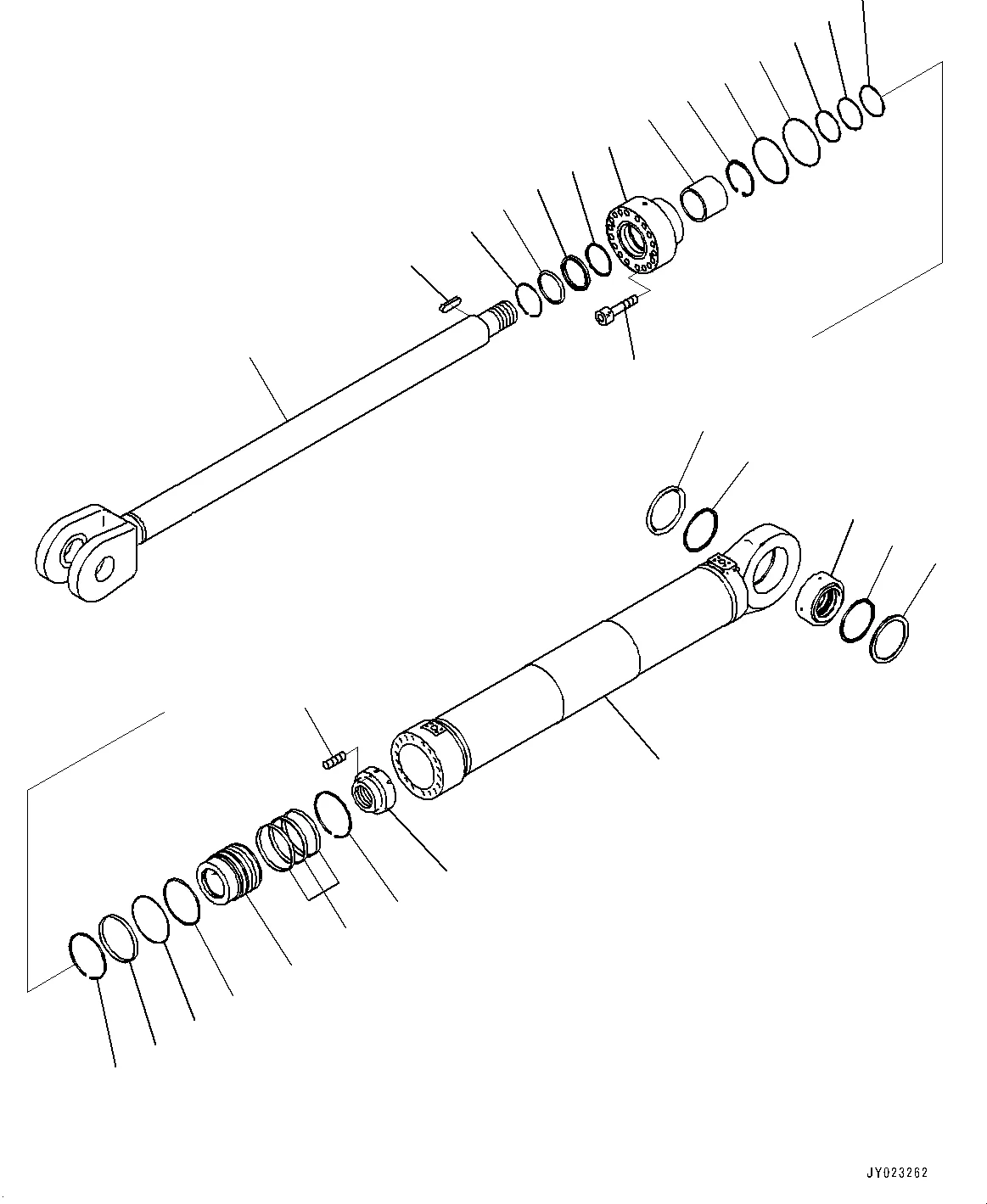

Piston pumps are more high pressure and more efficient than a gear pump. Piston pumps operate using linear action (interchangeably) to displace the fluid into a pulsating flow manner. Multiple pistons working out of phase can reduce this pulsation.

Pneumatic pumps are also often used to transport fluids, thanks to their extremely high-pressure abilities – for these reasons, they are often suited for high power applications such as heavy equipment construction, injection-molding machines, and high-pressure hydraulic presses.

Vane Pumps

Vane pumps, which have rotating vanes in a circular casing, deliver a more consistent flow than piston pumps. They provide a balance of pressure and flow capabilities and are typically small and easy to maintain.

Vane pumps are used in diverse applications ranging from agriculture machines as well as power steering systems in vehicles, to industrial automation and material handling equipment.

The right hydraulic pump will depend upon the pressure, flow rate, and efficiency needs of the specific application. Comprehending these subtleties is key for the best balance of efficiency and cohesion a system can achieve.

Pump Types Gear Pumps: One of the simplest types of pumps, gear pumps use meshing gears to draw fluid into the pump and push it back out under pressure. They are well-built, inexpensive, and flow at a relatively unchanging rate. On the other hand, they become less efficient in high-pressure conditions and can wear out over time.

Gear pumps are mainly used in low pressure, high volume applications like industrial machinery, lubrication systems, and low pressure hydraulic systems.

Piston Pumps

Piston pumps are more high pressure and more efficient than a gear pump. Piston pumps operate using linear action (interchangeably) to displace the fluid into a pulsating flow manner. Multiple pistons working out of phase can reduce this pulsation.

Pneumatic pumps are also often used to transport fluids, thanks to their extremely high-pressure abilities – for these reasons, they are often suited for high power applications such as heavy equipment construction, injection-molding machines, and high-pressure hydraulic presses.

Vane Pumps

Vane pumps, which have rotating vanes in a circular casing, deliver a more consistent flow than piston pumps. They provide a balance of pressure and flow capabilities and are typically small and easy to maintain.

Vane pumps are used in diverse applications ranging from agriculture machines as well as power steering systems in vehicles, to industrial automation and material handling equipment.

The right hydraulic pump will depend upon the pressure, flow rate, and efficiency needs of the specific application. Comprehending these subtleties is key for the best balance of efficiency and cohesion a system can achieve.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)