PRODUCTS

Exploring the Mechanics and Applications of Hydraulic Pumps in Modern Engineering Systems for Efficient Power Transmission and Fluid Control Solutions

2025-04-11

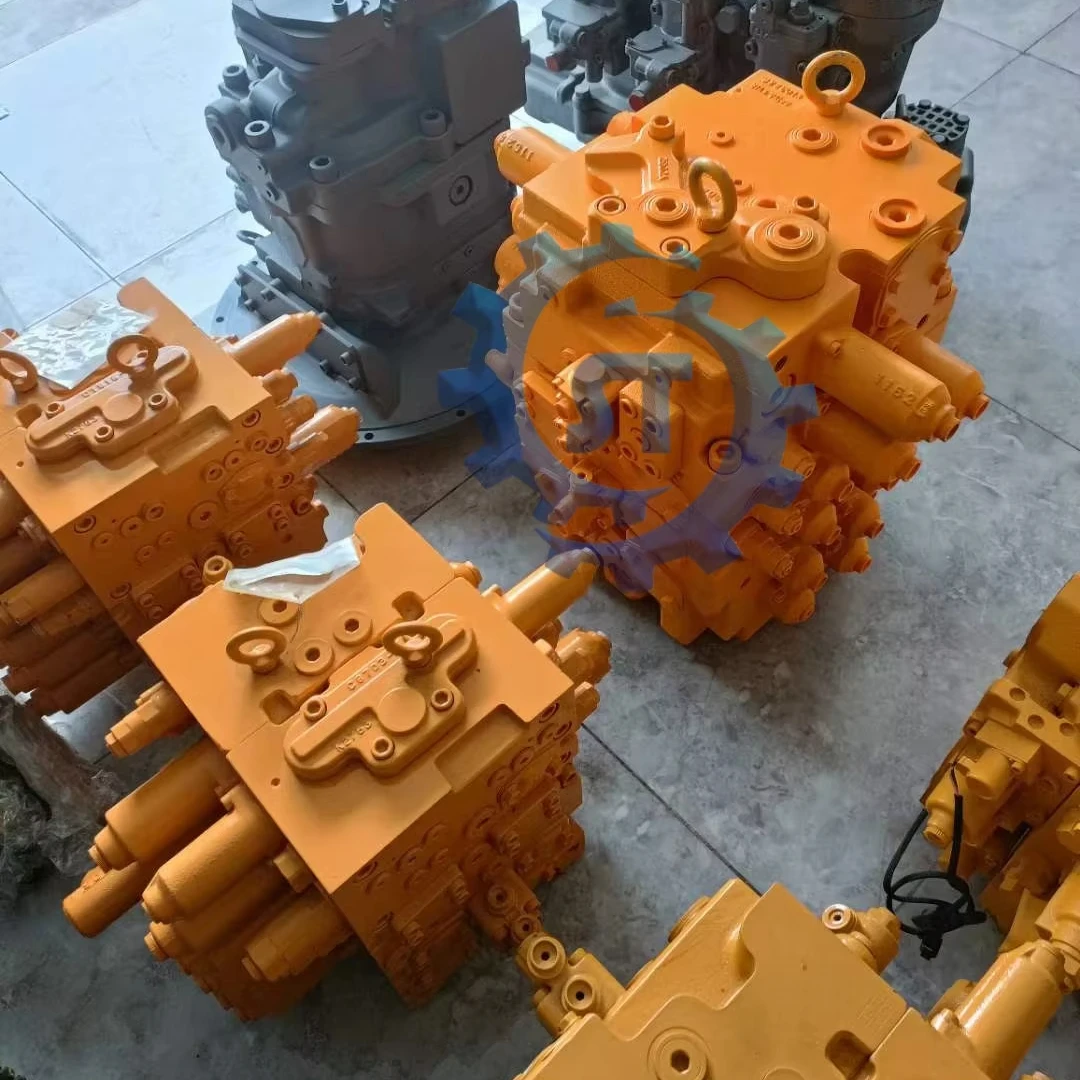

Today we can say, hydraulic pumps are the heart of the modern engineering system, indispensable when it comes to efficient power transmission and fluid control solution. They are used to transfer mechanical energy into hydraulic energy to mobilize fluids, control them accordingly, and use them in different industrial and mechanical applications. Hydraulic pumps are the backbone of many industries, from construction machinery to aerospace systems, thanks to their reliability, precision, and high-pressure capabilities. This article explains the working of hydraulic pumps, their different applications, and the new advancements that to help in the evolution of hydraulic pumps and expand their uses in modern engineering.

Hydraulic pumps are, without a doubt, very important. These are a key components in all systems where accurate control of fluid is needed, such as in manufacturing processes, automotive and even renewable energy industries. Knowledge of how they operate and their applications helps an engineer to maximize efficiency, save power, and increase the lifespan of the system. In this exploration of hydraulic pumps, we aim to demystify these essential components, offering insights into their workings, types, and the innovations that will influence their future.

Understanding How Hydraulic Pumps Work

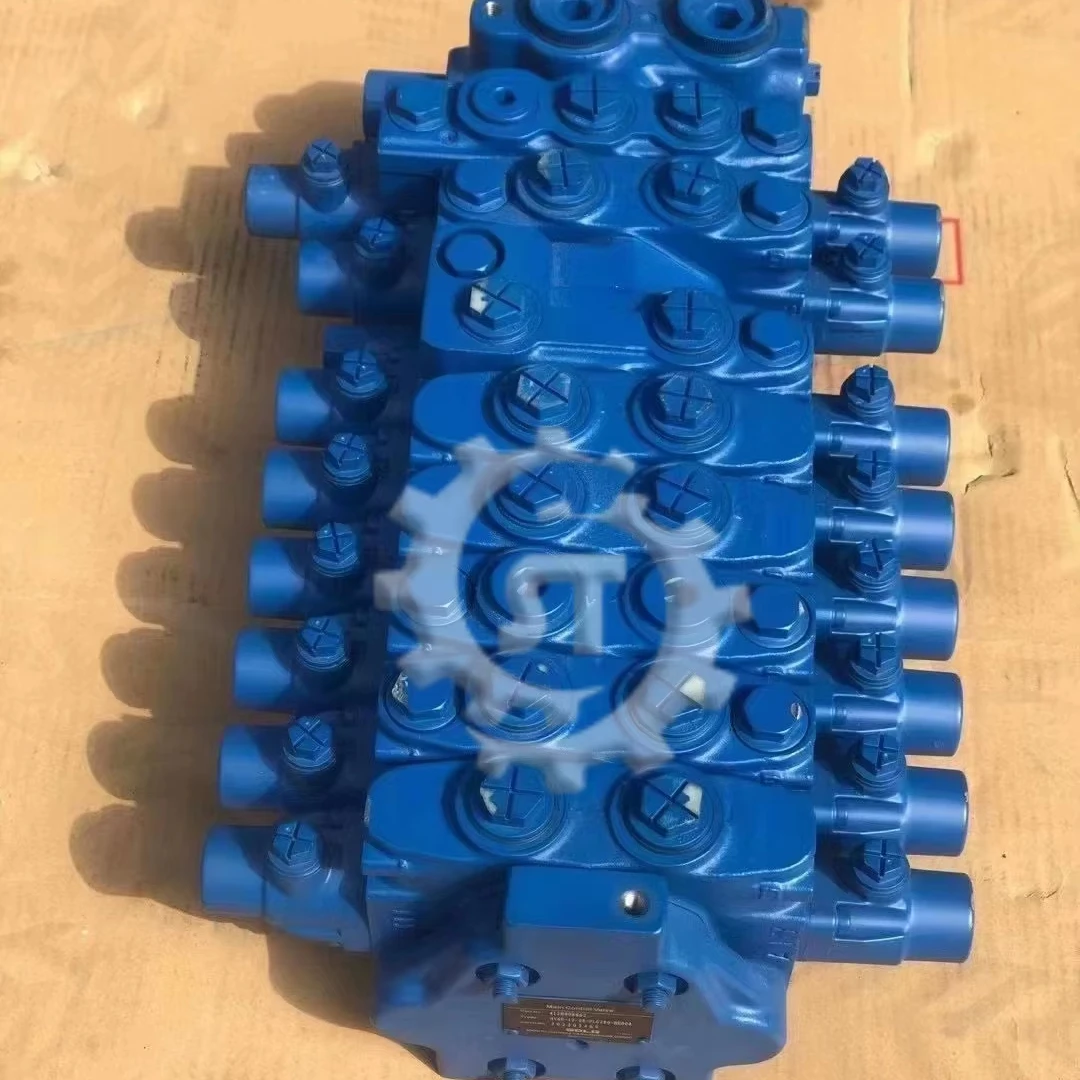

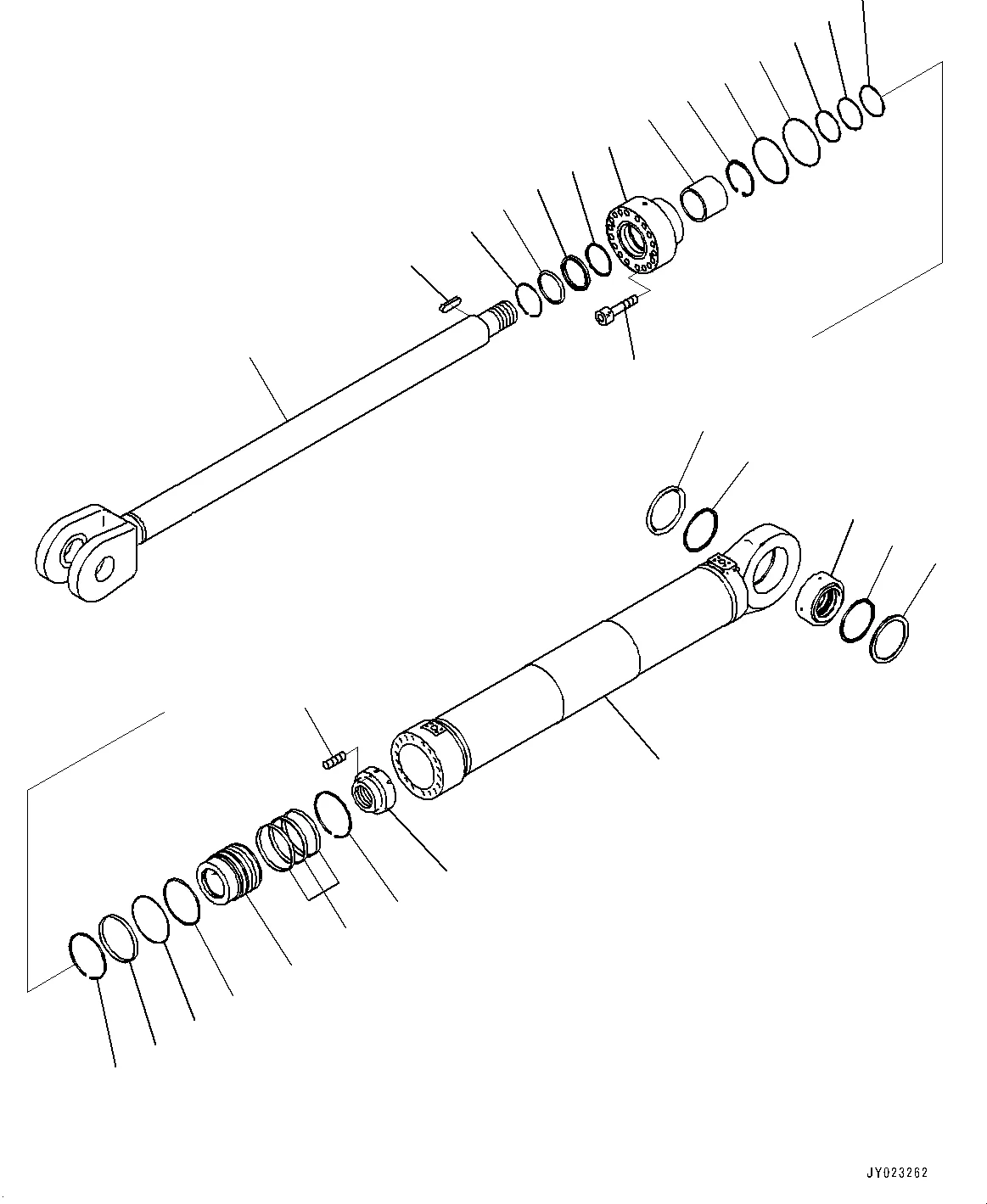

Hydraulic pumps are based on the principle of displacement where mechanical action generates a vacuum to draw the fluid into the pump and then discharge it under hydraulic pressure. Note that the design of a hydraulic pump is application dependent, and it may have lots of implications on the efficiency. Types vary widely; there are gear pumps, vane pumps and piston pumps, and each different pump type employs its own mechanism suited for a specific task.

For example, gear pumps which utilize meshing of gears to move fluid. These valves are recognized for their simplicity and longevity, as they are perfect low-to-medium pressure valves. Vane pumps, on the other hand, feature sliding vanes to create chambers that trap and transport fluid. These pumps are higher efficiency and commonly used in automotive hydraulic power steering systems. Piston pumps are the most complex of the three and use reciprocating pistons to achieve high pressure, appropriate for heavy industrial machinery.

Fluid viscosity, temperature and system pressure affects the hydraulic pump performance. Engineers need to choose the right kind of pump and material to operate efficiently under changing conditions. The improvements shown with CFD and particularly with the ability to model materials have taken this a step further giving these pumps a much more reliable and prescribed performance in ever more difficult environments.

Modern Engineering Systems Applications

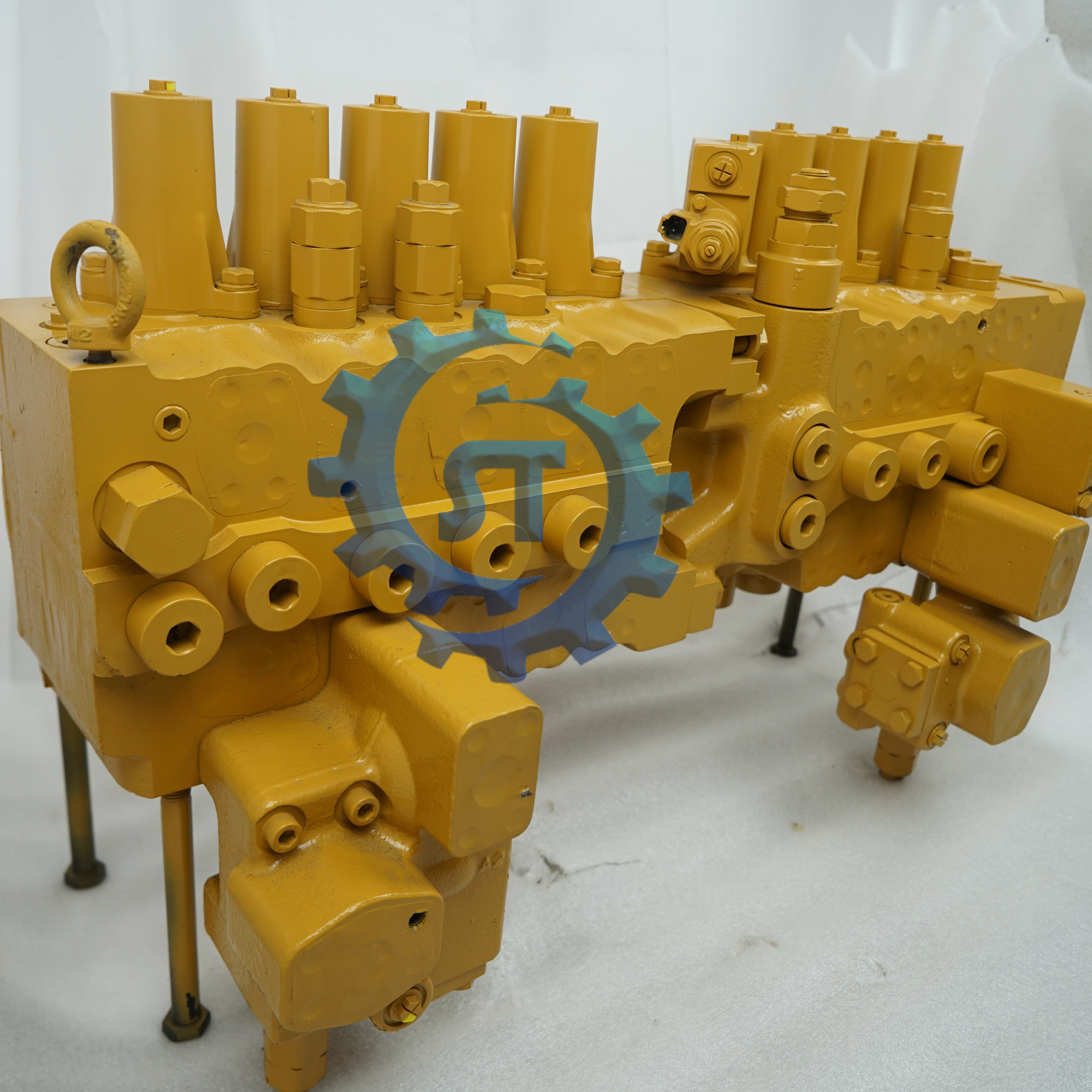

Hydraulic pumps have become a common piece of machinery in modern engineering, used frequently in many fields. They work excavators, cranes, and bulldozers in construction, giving the power to lift heavy loads and make precise movements. Hydraulic systems are an essential part of this sector where endurance and strength are prime focus areas due to their strength and scalability.

For the automotive industry, braking & steering system hydraulic pumps are importance component. Safety related systems like anti-lock braking systems (ABS), power steering also requires hydraulic pressure to be able to control the vehicle in a safe manner by resting on human controls. Hydraulic pumps play a crucial role in the aerospace sector as well, found in flight control systems, landing gear mechanisms, and other critical functions. Hydraulic pumps can work under extreme conditions thus preferred in these high stake environments.

Hydraulic pumps are also used in renewable energy systems like wind turbines and hydroelectric plants for transmission and control. Hydraulic systems in wind turbines regulate blade pitch while they pancake wings to make the most out of the wind that passes over them, and in hydroelectric plants, they control the flow of water that hits the fins to produce electricity. These uses demonstrate how hydraulic pumps can help meet many of the challenges posed by sustainable energy generation.

Innovations and Future Trends

Hydraulic pump production and supply technique is an emerging field, aiming to achieve innovation optimization for higher efficiency, sustainability and intelligent. A technology to highlight here is the recent innovation of electro-hydraulic pumps that combine electric motors with hydraulic systems for decreased energy consumption and increased precision. Such hybrid systems are useful in applications that have variable speed and load (such as industrial automation and robotics).

Getting popular is smart sensors and IoT (Internet of things) technology which help in monitoring, and optimization in hydraulic pump performance. Meanwhile, predictive maintenance driven by real-time data collection and analysis minimize downtime and prolong the lifespan of equipment. These changes lead to making hydraulic systems smart and accountable parts of the modern engineering networks.

The future of hydraulic pumps is also being influenced by environmental concerns. Sustainable_values_industry development of hydraulic fluids using biodegradable hydraulic fluids and energy-efficient pump designs However, with limitations on energy and emissions becoming even stricter, hydraulic pump manufacturers have to come up with greener technologies to combat this issue.

Conclusion

Hydraulic pumps have been an integral aspect of modern engineering providing efficient fluid control and power transmission in a complex array of applications. Based on the science of displacement and pressure, their mechanisms have been perfected through decades of refinement to provide unmatched performance and dependability. Hydraulic pumps that drive innovation and efficiency in various sectors – construction, automotive, aerospace, renewable energy, etc.

With advancements in technology, we can expect even more amazing features to be incorporated into hydraulic pumps through the evolution of electro-hydraulic systems, smart sensors, and sustainable practices. Through keeping up with these changes, engineers can utilize hydraulic systems in the optimal fashion to cater to the unique requirements of an industrial landscape that is constantly changing. The future of hydraulic pumps is promising, with many more innovations to come that will increase the efficiency of these tools, decrease environmental damage, and test the limits of engineering.

Hydraulic pumps are, without a doubt, very important. These are a key components in all systems where accurate control of fluid is needed, such as in manufacturing processes, automotive and even renewable energy industries. Knowledge of how they operate and their applications helps an engineer to maximize efficiency, save power, and increase the lifespan of the system. In this exploration of hydraulic pumps, we aim to demystify these essential components, offering insights into their workings, types, and the innovations that will influence their future.

Understanding How Hydraulic Pumps Work

Hydraulic pumps are based on the principle of displacement where mechanical action generates a vacuum to draw the fluid into the pump and then discharge it under hydraulic pressure. Note that the design of a hydraulic pump is application dependent, and it may have lots of implications on the efficiency. Types vary widely; there are gear pumps, vane pumps and piston pumps, and each different pump type employs its own mechanism suited for a specific task.

For example, gear pumps which utilize meshing of gears to move fluid. These valves are recognized for their simplicity and longevity, as they are perfect low-to-medium pressure valves. Vane pumps, on the other hand, feature sliding vanes to create chambers that trap and transport fluid. These pumps are higher efficiency and commonly used in automotive hydraulic power steering systems. Piston pumps are the most complex of the three and use reciprocating pistons to achieve high pressure, appropriate for heavy industrial machinery.

Fluid viscosity, temperature and system pressure affects the hydraulic pump performance. Engineers need to choose the right kind of pump and material to operate efficiently under changing conditions. The improvements shown with CFD and particularly with the ability to model materials have taken this a step further giving these pumps a much more reliable and prescribed performance in ever more difficult environments.

Modern Engineering Systems Applications

Hydraulic pumps have become a common piece of machinery in modern engineering, used frequently in many fields. They work excavators, cranes, and bulldozers in construction, giving the power to lift heavy loads and make precise movements. Hydraulic systems are an essential part of this sector where endurance and strength are prime focus areas due to their strength and scalability.

For the automotive industry, braking & steering system hydraulic pumps are importance component. Safety related systems like anti-lock braking systems (ABS), power steering also requires hydraulic pressure to be able to control the vehicle in a safe manner by resting on human controls. Hydraulic pumps play a crucial role in the aerospace sector as well, found in flight control systems, landing gear mechanisms, and other critical functions. Hydraulic pumps can work under extreme conditions thus preferred in these high stake environments.

Hydraulic pumps are also used in renewable energy systems like wind turbines and hydroelectric plants for transmission and control. Hydraulic systems in wind turbines regulate blade pitch while they pancake wings to make the most out of the wind that passes over them, and in hydroelectric plants, they control the flow of water that hits the fins to produce electricity. These uses demonstrate how hydraulic pumps can help meet many of the challenges posed by sustainable energy generation.

Innovations and Future Trends

Hydraulic pump production and supply technique is an emerging field, aiming to achieve innovation optimization for higher efficiency, sustainability and intelligent. A technology to highlight here is the recent innovation of electro-hydraulic pumps that combine electric motors with hydraulic systems for decreased energy consumption and increased precision. Such hybrid systems are useful in applications that have variable speed and load (such as industrial automation and robotics).

Getting popular is smart sensors and IoT (Internet of things) technology which help in monitoring, and optimization in hydraulic pump performance. Meanwhile, predictive maintenance driven by real-time data collection and analysis minimize downtime and prolong the lifespan of equipment. These changes lead to making hydraulic systems smart and accountable parts of the modern engineering networks.

The future of hydraulic pumps is also being influenced by environmental concerns. Sustainable_values_industry development of hydraulic fluids using biodegradable hydraulic fluids and energy-efficient pump designs However, with limitations on energy and emissions becoming even stricter, hydraulic pump manufacturers have to come up with greener technologies to combat this issue.

Conclusion

Hydraulic pumps have been an integral aspect of modern engineering providing efficient fluid control and power transmission in a complex array of applications. Based on the science of displacement and pressure, their mechanisms have been perfected through decades of refinement to provide unmatched performance and dependability. Hydraulic pumps that drive innovation and efficiency in various sectors – construction, automotive, aerospace, renewable energy, etc.

With advancements in technology, we can expect even more amazing features to be incorporated into hydraulic pumps through the evolution of electro-hydraulic systems, smart sensors, and sustainable practices. Through keeping up with these changes, engineers can utilize hydraulic systems in the optimal fashion to cater to the unique requirements of an industrial landscape that is constantly changing. The future of hydraulic pumps is promising, with many more innovations to come that will increase the efficiency of these tools, decrease environmental damage, and test the limits of engineering.

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)