PRODUCTS

Exploring the Significance of Hydraulic Cylinders for Excavator Functionality

2025-09-02

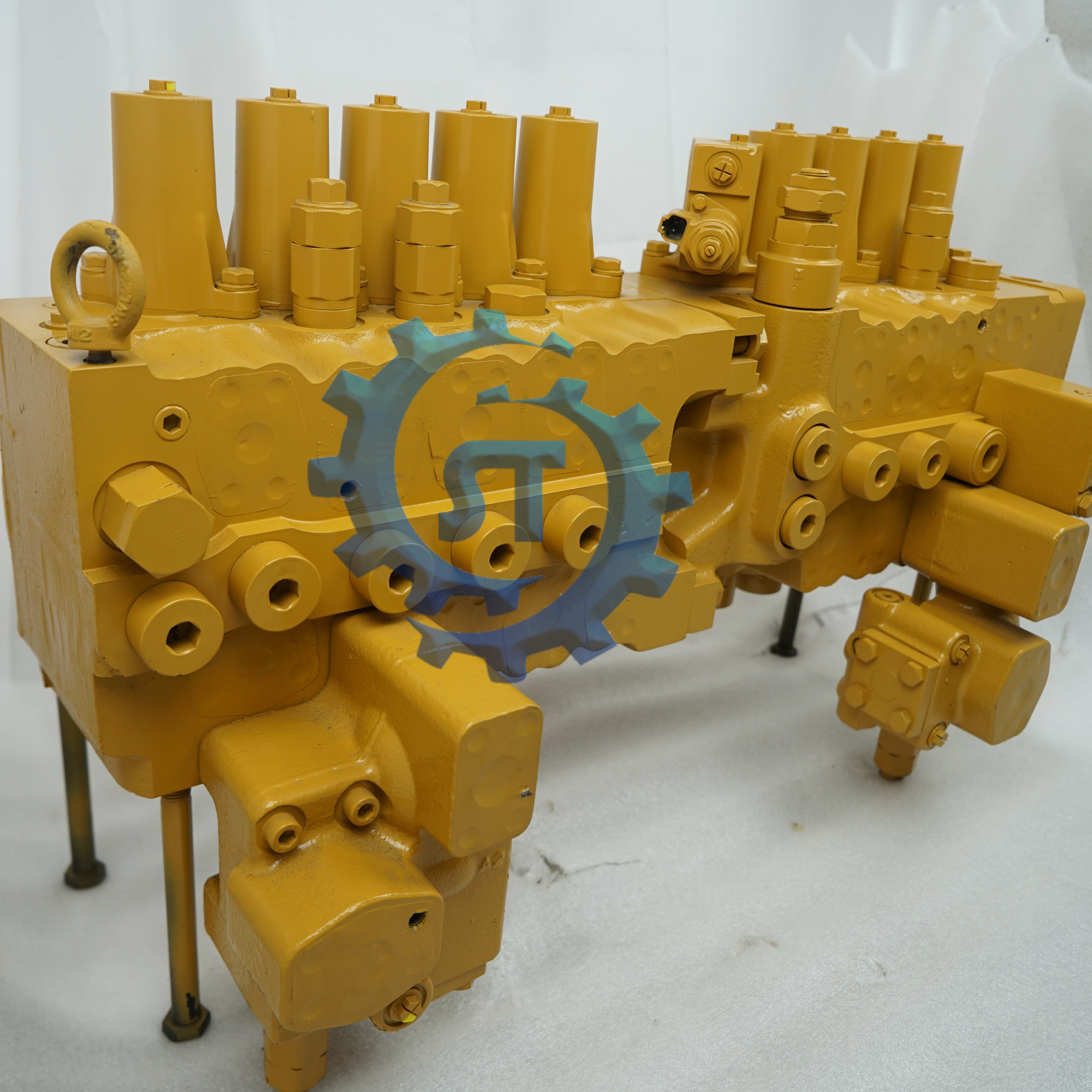

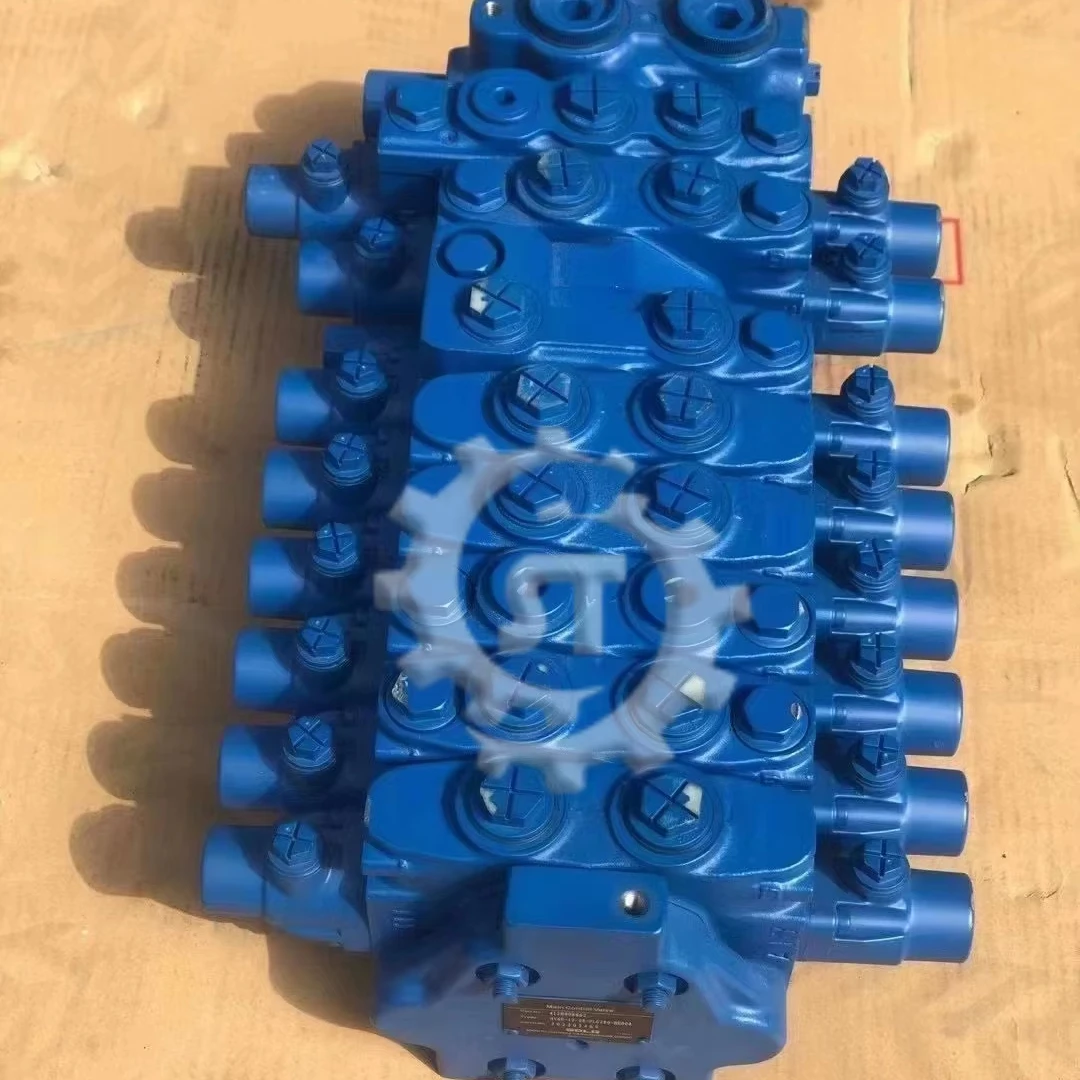

Excavator hydraulics power nearly all the force and precision of excavator operations, and hydraulic cylinders are the central link in this elaborate chain. Understanding their significance allows us to expand our horizons when it comes to the things we can appreciate that the machine does. Power and Movement

Hydraulic cylinders — the digger muscles, turning flesh to hydraulic pressure to subdue the king of the ground with a ball of sky. This gives the arm digging, lifting, and swinging capability — which are fundamental movements needed for excavation. The size of the cylinder and the pressure in the system directly correlate with this force and produce the power needed to push massive amounts of earth.

So these are like specific precision—high precision-like but less precise control. Fine movement - With hydraulic flow control, precision can be achieved when handling delicate tasks.

Diverse Applications

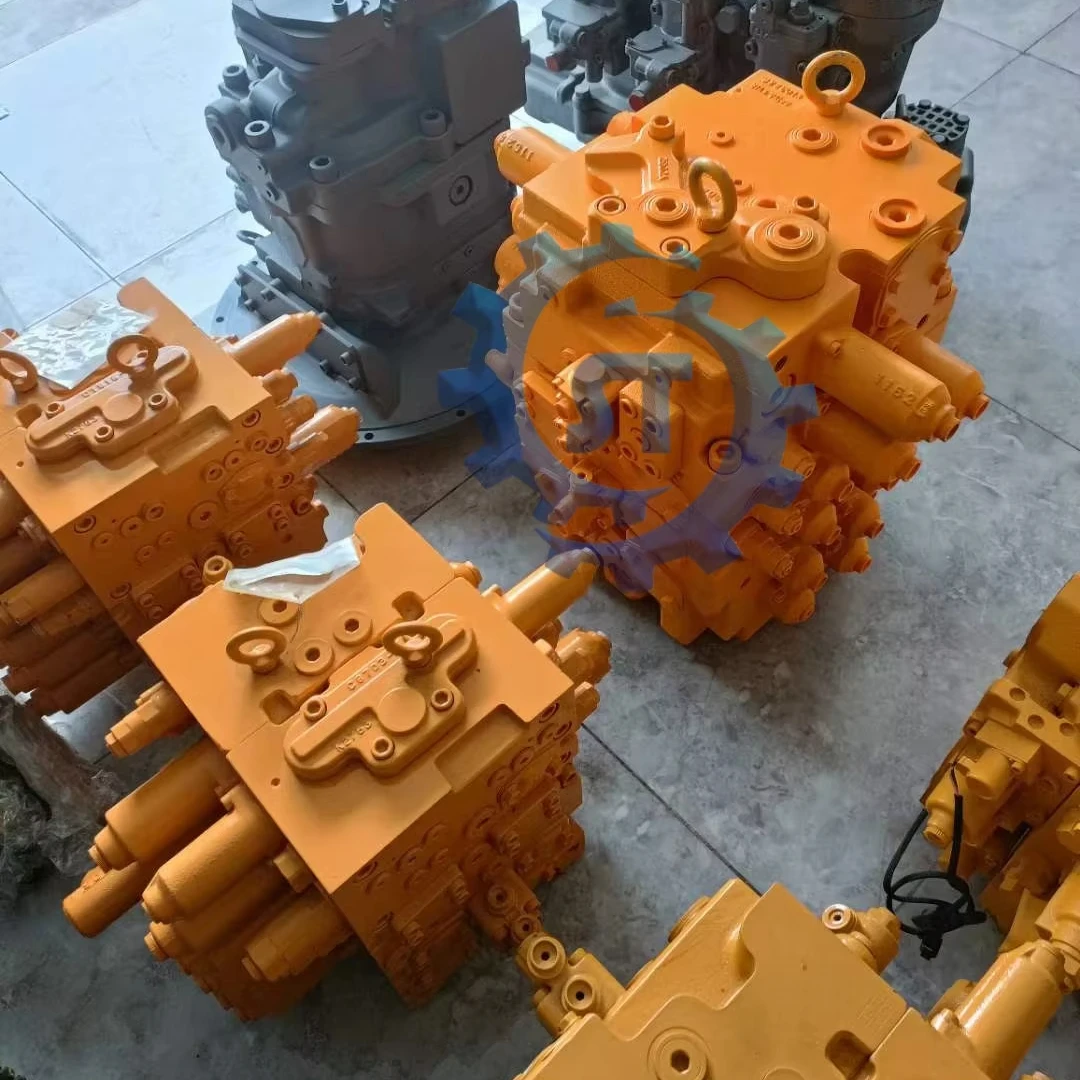

From the smallest bucket cylinders off the main boom and stick, everything has its place… right? The boom has a vertical extension (boom cylinder) and the stick (stick cylinder) controls the extension and retraction of the digging arm. Even the smaller swing cylinder assists in rotating the full body of the excavator.

That is a tribute to the versatility of the cylinder making it so wide-ranging use. Based on the design criteria of the different types of excavators and the operating needs.

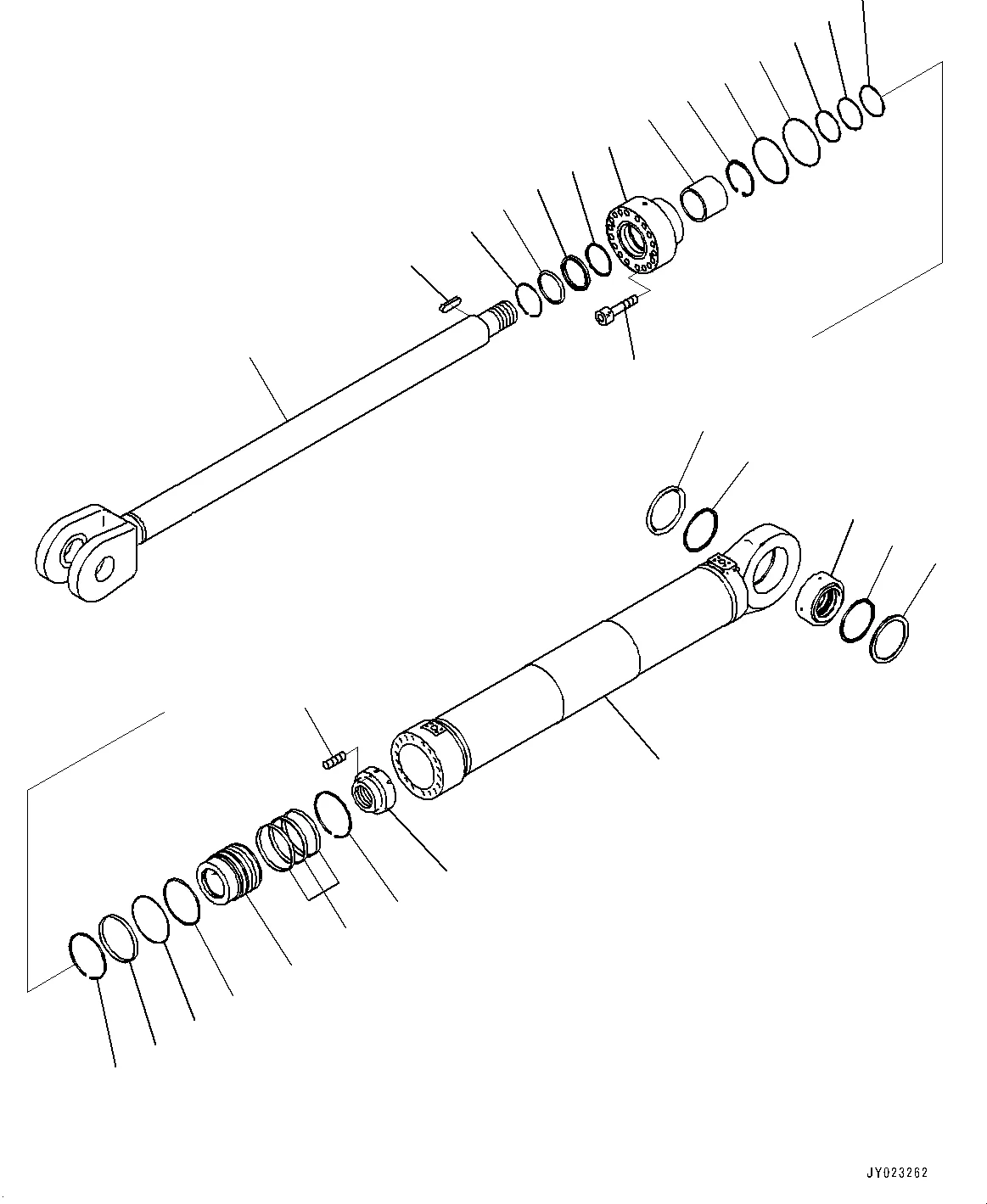

Reliability and Maintenance

Hydraulic cylinders can last for a long time, but they need proper maintenance to work efficiently. Whether to find leaks or check for damages, these inspections are essential to ensure optimal functionality while preventing failures that can cost you dearly.

If you want to troubleshoot the hydraulic cylinder or maintain it in the best possible way, you must know how it works. You can send as well as fix any issues faster.

Hydraulic cylinders — the digger muscles, turning flesh to hydraulic pressure to subdue the king of the ground with a ball of sky. This gives the arm digging, lifting, and swinging capability — which are fundamental movements needed for excavation. The size of the cylinder and the pressure in the system directly correlate with this force and produce the power needed to push massive amounts of earth.

So these are like specific precision—high precision-like but less precise control. Fine movement - With hydraulic flow control, precision can be achieved when handling delicate tasks.

Diverse Applications

From the smallest bucket cylinders off the main boom and stick, everything has its place… right? The boom has a vertical extension (boom cylinder) and the stick (stick cylinder) controls the extension and retraction of the digging arm. Even the smaller swing cylinder assists in rotating the full body of the excavator.

That is a tribute to the versatility of the cylinder making it so wide-ranging use. Based on the design criteria of the different types of excavators and the operating needs.

Reliability and Maintenance

Hydraulic cylinders can last for a long time, but they need proper maintenance to work efficiently. Whether to find leaks or check for damages, these inspections are essential to ensure optimal functionality while preventing failures that can cost you dearly.

If you want to troubleshoot the hydraulic cylinder or maintain it in the best possible way, you must know how it works. You can send as well as fix any issues faster.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)