PRODUCTS

Hydraulic Cylinder Material Selection Impact on Reliability and Longevity

2025-07-11

The materials selected for hydraulic cylinders, which are essential for many industrial and construction applications, play a pivotal role. The choice not only has an influence on the reliability but also the life of these key components. Knowledge of these material selections is essential in operating in an under-capacity and safe manner. Strength and Durability

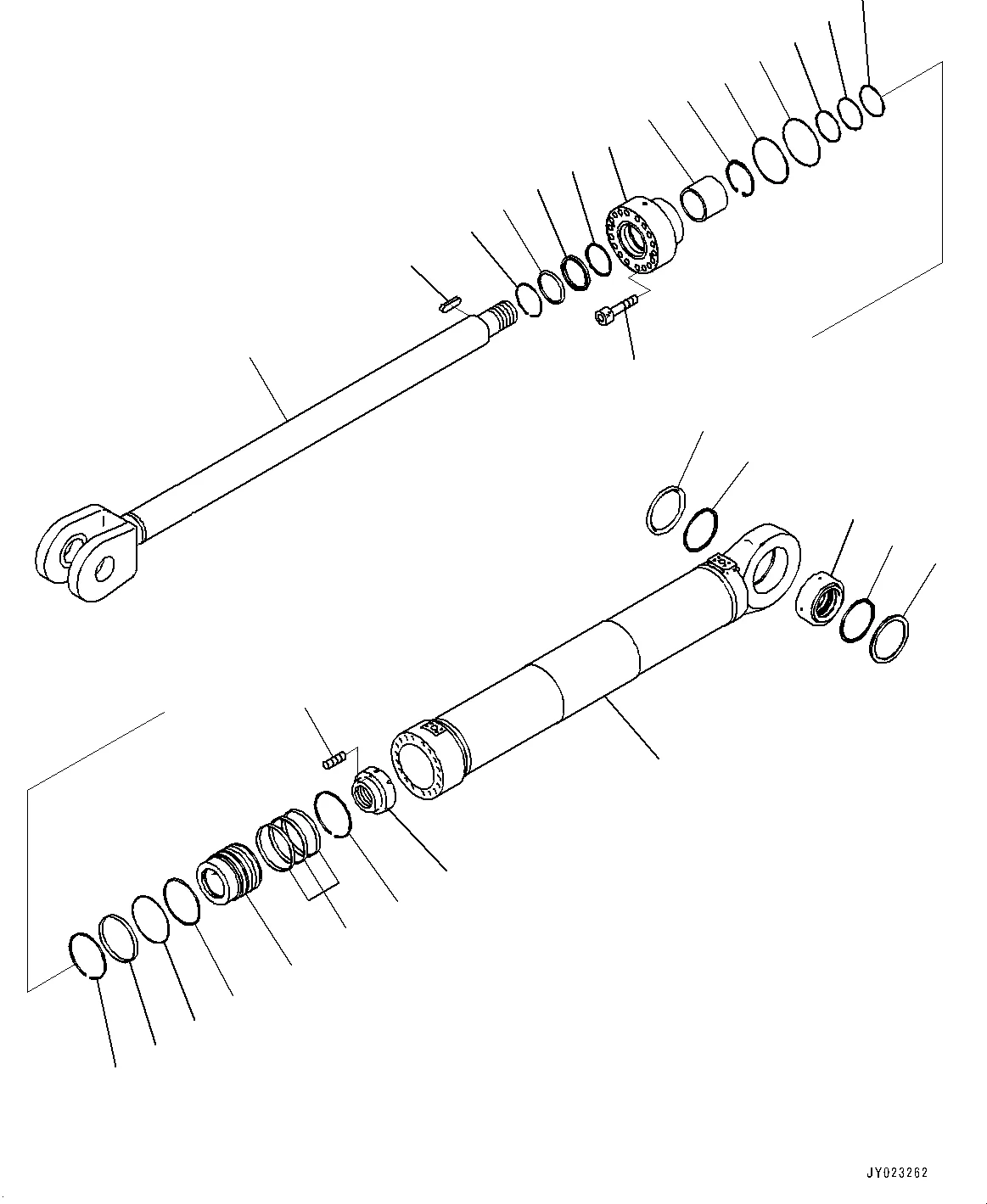

The main part of the cylinder is usually a tube that must sustain high internal pressures. Commonly used materials include high-strength steels, such as alloy steels, or stainless steels, which provide high yield strength and fatigue strength. Selection of either single side or double side depends on the pressure needs of the application, and the environment in which it operates as a corrosive environment. At very high pressures some exotic material such as advanced composites could be used.

In addition, piston rod is exposed to a high-level bending and compressive load so need material which will posses high tensile strength and wear resistance. A common material is hardened steel, usually chrome plated, which is a good compromise between hardness and corrosion resistance. It needs to be selected to account for the loads and for wear and tear.

Corrosion Resistance

Often, hydraulic cylinders operate in environments that are not so favorable, holding moisture, being exposed to chemical parts and extreme temperatures. Therefore, corrosion resistance is paramount. Due to the natural corrosion resistance stainless steels provide, they provide lower maintenance and life cycle costs. In especially hostile environments, chrome plating, zinc plating, or specific types of paint may be used to further increase anode protection.

If dissimilar metals are in contact, the potential for galvanic corrosion will also necessitate some selection of material. Prevent premature failure due to electrochemical reactions, common practice requiring careful consideration of material compatibility.

Cost and Availability

Although performance is paramount, cost and availability of the material are practical considerations as well. It is necessary to select a material that will balance performance demands against costs. High-performance materials could have a longer service life, but this higher cost may not be reasonable in every application. Responsible material selection means balancing performance alongside economic considerations.

The main part of the cylinder is usually a tube that must sustain high internal pressures. Commonly used materials include high-strength steels, such as alloy steels, or stainless steels, which provide high yield strength and fatigue strength. Selection of either single side or double side depends on the pressure needs of the application, and the environment in which it operates as a corrosive environment. At very high pressures some exotic material such as advanced composites could be used.

In addition, piston rod is exposed to a high-level bending and compressive load so need material which will posses high tensile strength and wear resistance. A common material is hardened steel, usually chrome plated, which is a good compromise between hardness and corrosion resistance. It needs to be selected to account for the loads and for wear and tear.

Corrosion Resistance

Often, hydraulic cylinders operate in environments that are not so favorable, holding moisture, being exposed to chemical parts and extreme temperatures. Therefore, corrosion resistance is paramount. Due to the natural corrosion resistance stainless steels provide, they provide lower maintenance and life cycle costs. In especially hostile environments, chrome plating, zinc plating, or specific types of paint may be used to further increase anode protection.

If dissimilar metals are in contact, the potential for galvanic corrosion will also necessitate some selection of material. Prevent premature failure due to electrochemical reactions, common practice requiring careful consideration of material compatibility.

Cost and Availability

Although performance is paramount, cost and availability of the material are practical considerations as well. It is necessary to select a material that will balance performance demands against costs. High-performance materials could have a longer service life, but this higher cost may not be reasonable in every application. Responsible material selection means balancing performance alongside economic considerations.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)