PRODUCTS

Hydraulic Cylinder Material Selection Key Factors for Optimal Performance

2025-07-15

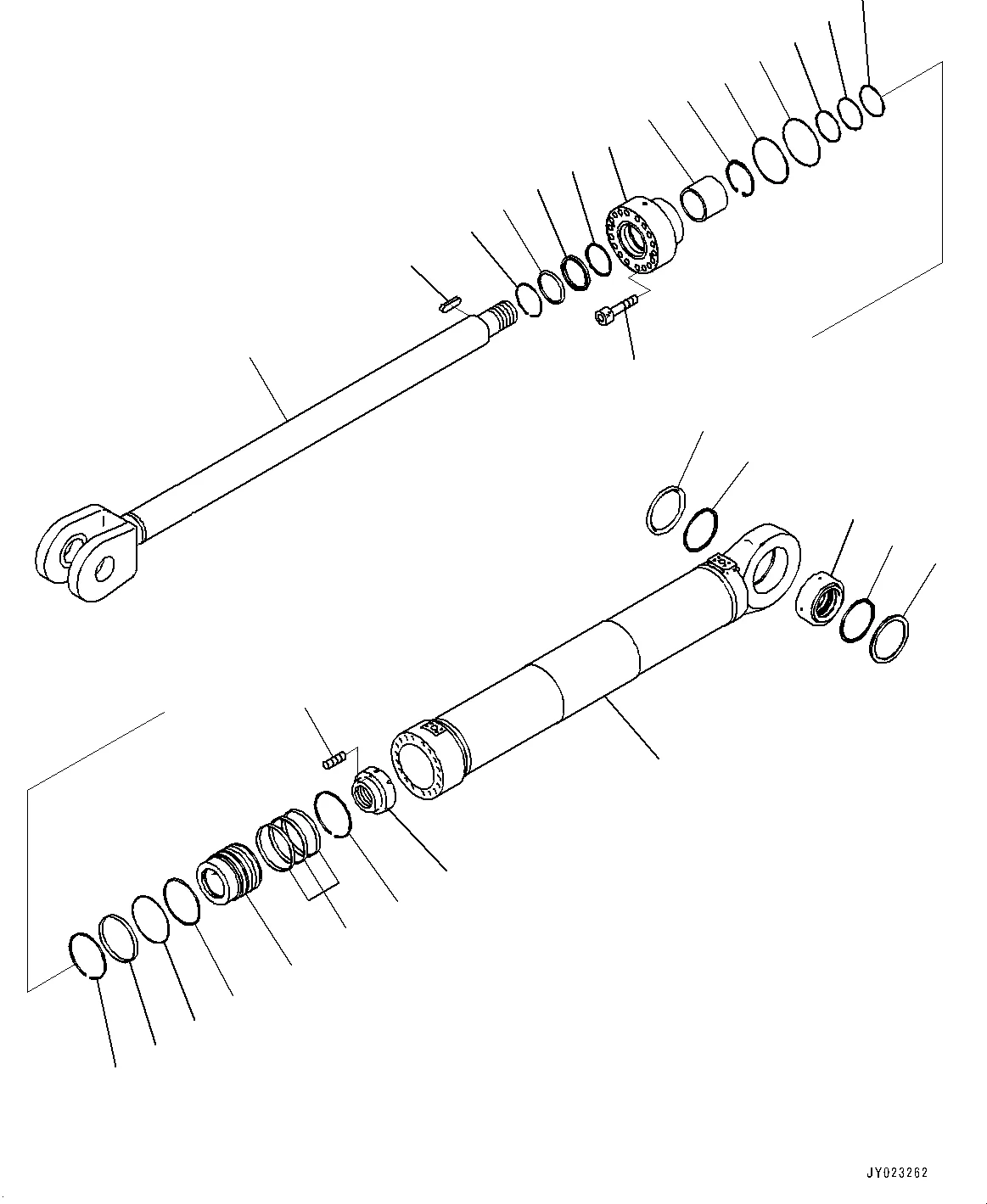

One of the hardest-working components in industrial machinery, hydraulic cylinders are heavily dependent on the materials from which they are produced. The role of selection process is significant, as it will affect strength, durability, and cost-effectiveness. Incorrect material selection may cause premature failure, expensive line-down time, and safety risk. Here are some of the more important drivers of material choice for these important elements. Strength and Durability

Top priority is the cylinder, which must be able to withstand high internal pressures. High strength steel alloys, for instance, provide strong tensile strength and yield strength to resist catastrophic failure under load. It is a tradeoff between power and weight often, and in mobile applications, weight is always king as the goal is to avoid carrying mass.

Additionally, hardness is important to help reduce wear from this constant movement and from the movement of the piston rod through the seals. Surface treated by hard chrome plating or nitriding, which provides wear resistance and improves the cylinder\'s life.

Corrosion Resistance

Due to exposure to many different fluids and environments, this requires corrosion resistance. One of the most common materials, stainless steels, offers great corrosion and rust resistance because they are made with certain metals that are naturally resistant to rust and degradation. The only downside that restricts some applications is the price. Protection could be a coating or use of alternative metal(s) depending on the exact environment.

Selection should also take into account the aggressive nature of the hydraulic fluid. It is essential because incompatible materials can degrade, resulting in undesirable leaks and contamination of fluids.

Cost-Effectiveness

It is necessary to balance performance requirements with budget consequences. A high-performance high-strength steel alloy is going to outperform most other options, although cheaper options like cast iron do exist for low-pressure scenarios. Material and project cost must be optimised through a proper cost-benefit analysis.

The overall cost is also influenced by the method of manufacture and the availability of the material. Cutting time and costs: Easily machined materials that positively influence the price of the final product.

Top priority is the cylinder, which must be able to withstand high internal pressures. High strength steel alloys, for instance, provide strong tensile strength and yield strength to resist catastrophic failure under load. It is a tradeoff between power and weight often, and in mobile applications, weight is always king as the goal is to avoid carrying mass.

Additionally, hardness is important to help reduce wear from this constant movement and from the movement of the piston rod through the seals. Surface treated by hard chrome plating or nitriding, which provides wear resistance and improves the cylinder\'s life.

Corrosion Resistance

Due to exposure to many different fluids and environments, this requires corrosion resistance. One of the most common materials, stainless steels, offers great corrosion and rust resistance because they are made with certain metals that are naturally resistant to rust and degradation. The only downside that restricts some applications is the price. Protection could be a coating or use of alternative metal(s) depending on the exact environment.

Selection should also take into account the aggressive nature of the hydraulic fluid. It is essential because incompatible materials can degrade, resulting in undesirable leaks and contamination of fluids.

Cost-Effectiveness

It is necessary to balance performance requirements with budget consequences. A high-performance high-strength steel alloy is going to outperform most other options, although cheaper options like cast iron do exist for low-pressure scenarios. Material and project cost must be optimised through a proper cost-benefit analysis.

The overall cost is also influenced by the method of manufacture and the availability of the material. Cutting time and costs: Easily machined materials that positively influence the price of the final product.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)