PRODUCTS

Hydraulic Pump Types A Detailed Look at Gear Piston and Vane Pumps

2025-07-31

From critical systems to heavy machinery or precision manufacturing, hydraulic systems play an important role in many industrial applications. The heart of each hydraulic system is an electric or gas powered hydraulic pump that is the source of actual hydraulic fluid pressure. Next comes an understanding of hydraulic pumps in practical applications by engineers and technicians. This article focuses on the widely used types of positive displacement pumps—gear, piston and vane—with their characteristics and uses. Gear Pumps

Gear pumps are of simple working, and are inexpensive. They are consisting of a housing with a pair of meshed gear, a drive and a driven gear, rotating. Fluid gets trapped in between the teeth of the gears and the case as the gears turn, and is moved from the inlet to the outlet. Except for pressure, low viscosity, the gear pump provides non52 low58 an59 o3-57/47957-2.

However, these have poor efficiency at higher pressures since they provide leakage paths between the gears and the casing. However, while they offer a less robust build, this does also mean that they welcome a bit more regular maintenance in the form of wear and tear.

Piston Pumps

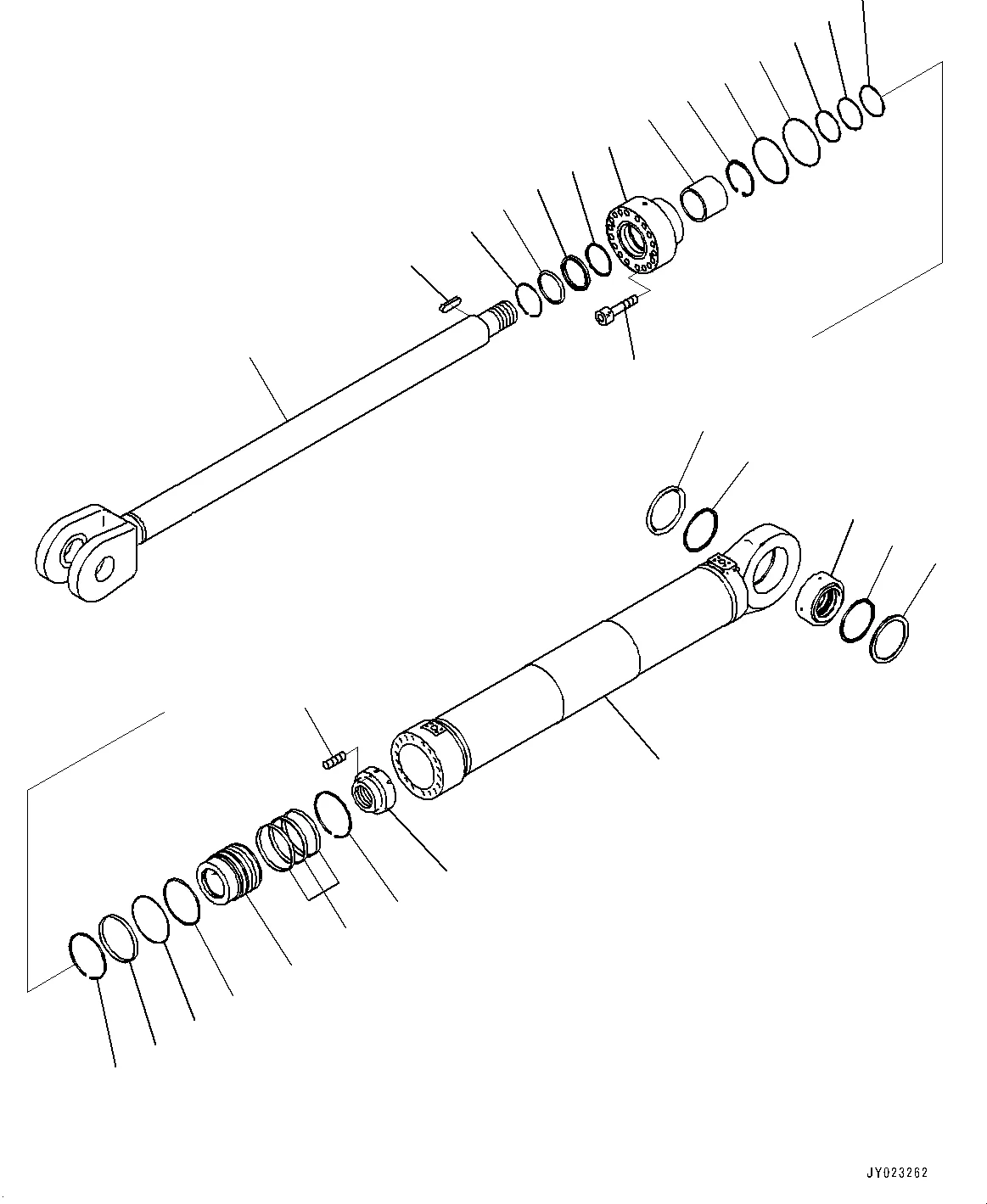

Piston pumps have higher pressure capabilities than gear pumps. They operate in similarity to reciprocating pistons in cylinders, pulling fluid in on the suction stroke, then forcing it out on the discharge stroke. Hence, it provides a power of periodic nature – this could be damped out by set of accumulators or by using more than one pistons for obtaining a continuous flow.

But, in case you are. Handle a high-pressure fluid of very high viscosity then, you piston pump must be there versatile Piston pumps, which have the versatility to capture numerous applications. Due to high efficiency and reliability, they are designed for the tougher applications, but are generally also more complex and expensive than the gear pumps.

Vane Pumps

Vane Pumps are intermediate between gear and piston pumps in pressure and complexity. In the rotor casing, they employ a sliding-vane rotor. As the rotor turns, the vanes trap and carry hydraulic fluid in chambers.

Vane pumps are pretty much a compromise between both the pressure range and efficiency – cost as well. They are less prone to leaking compared to gear pumps and suitable for low- to medium-pressure and flow applications. However, they are susceptible to both vane and rotor wear.

Gear pumps are of simple working, and are inexpensive. They are consisting of a housing with a pair of meshed gear, a drive and a driven gear, rotating. Fluid gets trapped in between the teeth of the gears and the case as the gears turn, and is moved from the inlet to the outlet. Except for pressure, low viscosity, the gear pump provides non52 low58 an59 o3-57/47957-2.

However, these have poor efficiency at higher pressures since they provide leakage paths between the gears and the casing. However, while they offer a less robust build, this does also mean that they welcome a bit more regular maintenance in the form of wear and tear.

Piston Pumps

Piston pumps have higher pressure capabilities than gear pumps. They operate in similarity to reciprocating pistons in cylinders, pulling fluid in on the suction stroke, then forcing it out on the discharge stroke. Hence, it provides a power of periodic nature – this could be damped out by set of accumulators or by using more than one pistons for obtaining a continuous flow.

But, in case you are. Handle a high-pressure fluid of very high viscosity then, you piston pump must be there versatile Piston pumps, which have the versatility to capture numerous applications. Due to high efficiency and reliability, they are designed for the tougher applications, but are generally also more complex and expensive than the gear pumps.

Vane Pumps

Vane Pumps are intermediate between gear and piston pumps in pressure and complexity. In the rotor casing, they employ a sliding-vane rotor. As the rotor turns, the vanes trap and carry hydraulic fluid in chambers.

Vane pumps are pretty much a compromise between both the pressure range and efficiency – cost as well. They are less prone to leaking compared to gear pumps and suitable for low- to medium-pressure and flow applications. However, they are susceptible to both vane and rotor wear.

https://www.songteparts.com

Give Us What You Need

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!

We will contact you within 24 hours after receiving the information

SUBSCRIBE

INQUIRY

_5t33iQdr.png)